Technical data-sheet & process to segregate pure iron from induction F/C slag

PEIE Design, Engineering, Manufacture, shop-test , Supply, Erection & commissioning 2nd generation Slag Crushing & Beneficiations Plant in TPM methodology with following customer delighting features.

|

DESIGN BASE (Induction Furnace Slag) |

10 Ton/hour |

15 Ton/hour |

20 Ton/hour |

5 Ton/hour |

|

|

THROUGH INPUT |

>10% iron |

10 Ton/hour |

15 Ton/hour |

20 Ton/hour |

5 Ton/hour |

|

Lump Size |

≤ 300 mm 3 |

≤ 300 mm 3 |

≤ 350 mm 3 |

≤ 300 mm 3 |

|

|

OUTPUT |

> 75% Fe |

>1.7 Ton/hour |

>2.2 Ton/hour |

>3.5 Ton/hour |

>0.7 Ton/hour |

|

Grit Size |

≤ 4 mm |

Yes |

Yes |

Yes |

|

|

MODEL |

PEIE |

PEIE-10-X |

PEIE-15-X |

PEIE-25-X |

PEIE-5-X |

|

Material Handling |

No. of Conveyors |

4 to 8 nos |

Yes |

Yes |

Yes |

|

Equipments |

No. of Rotary Eqpts. |

5 nos |

Yes |

Yes |

Yes |

|

Input Hopper |

Ground Hopper size |

9 M² |

12 M² |

12 M² |

9 M² |

|

Jaw Crusher |

Jaw Size (Wide X Length) |

600 X 750 |

900 X 1200 |

900 X 1200 |

500 X 700 |

|

Roller Crusher |

Rotor Size |

900 X 900 |

900 X 1200 |

900 X 1200 |

675 x 675 |

|

Magnetic.Separator |

Drum X Length |

Ø750 X 1800 |

Ø1200X 1800 |

Ø1200X 1800 |

Ø600 X 1500 |

|

Vibrating screen |

Length X W X Height |

later |

later |

later |

later |

|

Hammer Mill |

Chamber size (Dia mm) |

Ø1000 mm (2.5tph) |

Ø1370 mm (5thp) |

Ø1000X1000 (10tph) |

later |

|

Area covered |

|

later |

later |

later |

later |

|

Power Required |

Drive |

133.7 KW |

later |

161.5 KW |

later |

|

After-sale service |

Training, technical support, etc. |

Yes |

Yes |

Yes |

Yes |

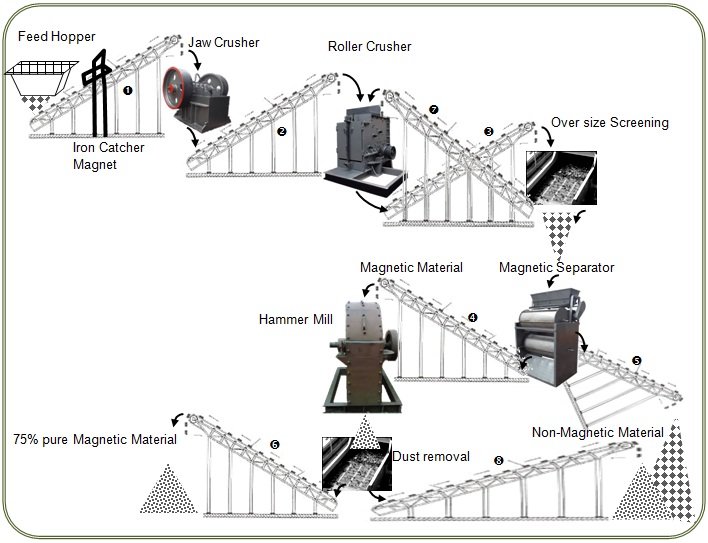

PROCESS BENEFICIATION TO > 75% Fe

JAW CRUSHER

|

DESIGN BASE |

10 Ton/hour |

15 M3/hour |

20 M3/hour |

5 Ton/hour |

|

|

General Information |

Model |

PEIE-10-X |

PEIE-15-X |

PEIE-20-X |

PEIE-5-X |

|

|

Feeder Opening (mm) |

250-400 mm |

400-600 mm |

400-600 mm |

200-350 mm |

|

|

Max. Feeding Size (mm) |

10”-15” |

10-18” |

10-18” |

10”-12” |

|

|

Output Size |

2” – 4” |

yes |

yes |

yes |

|

|

Motor Power KW X R.P.M |

37 / 1440 |

37 /1440 |

52 / 960 |

22 / 960 |

|

Overall Dimensions (mm) |

L X H X W |

48”x34”x26” |

later |

70”x46”x39” |

later |

|

Jaw Size |

(Width X Length) |

600 X 750 |

750 x 1050 |

900 X 1200 |

500 X 700 |

|

Body |

Size (L x H x W) |

48” x 34” x 26” |

|

70x46x39” |

|

|

Body & Toggle |

Fully fabricated M.S Plate IS-1062 |

25 to 60 mm |

25 to 60 mm |

30-60 mm |

25 to 60 mm |

|

Fly wheel |

heavy duty both sides |

Ø1070 |

later |

50” |

later |

|

|

Matls.- C.I gr.-I |

200 mm W |

later |

later |

later |

|

Jaw plate size |

One Fixed Plate (High Mn Steel Grade- III) |

720x590mm |

later |

45”X35.5” |

later |

|

|

One Moving Plate(High Mn Steel Grade- III) |

780x520mm |

later |

48”X31” | later |

|

Toggle & Outer Body |

fabricated in M.S |

25- 50mm |

later |

later | later |

|

Inner Crank |

material En-9 |

180mm diameter,. |

later |

later |

later |

|

Weight |

Approx. |

4.8 Ton |

later |

5.5 ton |

later |

|

After-sale service |

Training, technical support, etc. |

yes |

yes |

yes |

yes |

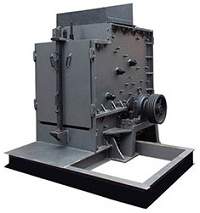

ROLLER CRUSHER

|

DESIGN BASE |

10 Ton/hour |

15 M3/hour |

20 M3/hour |

5 Ton/hour |

|

|

General Information |

Model |

PEIE-10-X |

PEIE-15-X |

PEIE-20-X |

PEIE-5-X |

|

|

Inlet Size (mm) |

50-100 |

50-100 |

50-125 |

50-100 |

|

|

Max. Feeding Size (mm) |

yes |

yes |

yes |

yes |

|

|

Output Size MM² |

2-15 |

yes |

yes |

yes |

|

|

Motor Power KW/R.P.M. |

37 / 960 |

37 / 960 |

52 / 960 |

22 / 960 |

|

Inner Rotor Size |

|

900 X 900 |

900 X 1200 |

914 X 1220 |

675 x 675 |

|

Body |

Size (L x H x W in MM) |

1778X1829X1194 |

|

1778X1829X1550 |

|

|

Body & Toggle |

Fully fabricated M.S Plate IS-1062 |

12-60 mm |

yes |

yes |

yes |

|

No. of Beater |

High Mn Steel Grade- III |

6 |

6 |

6 |

6 |

|

No.of adjustable weight |

|

2 |

2 |

2 |

2 |

|

Hardened blades & Inner Lining Material |

High Mn Steel Grade- III |

yes |

yes |

yes |

yes |

|

Toggle & Outer Body |

fabricated in M.S |

yes |

yes |

yes |

yes |

|

Inner Crank |

material En-9 |

Ø 180mm |

|

later |

later |

|

Weight |

Ton approx. |

7.5 |

8.5 |

9.5 |

6 |

|

After-sale service |

Training, technical support, etc. |

yes |

yes |

yes |

yes |

MAGNETIC SEPERATER

|

DESIGN BASE |

10 Ton/hour |

15 M3/hour |

20 M3/hour |

5 Ton/hour |

|

|

General Information |

Model |

PEIE-10-X |

PEIE-15-X |

PEIE-20-X |

PEIE-5-X |

|

|

Input Size (mm) |

0 - 15 |

yes |

yes |

yes |

|

|

Out put Size (mm) |

02- 15 |

yes |

yes |

yes |

|

Drum Size |

(Dia X Length) |

Ø750 X 1800 |

Ø750X 1800 |

Ø750X2174 |

Ø600X 1500 |

|

|

Motor Power (KW |

3.7+ |

later |

later |

later |

|

Overall Dimensions |

L X H X W |

1295X2005X 2134 |

1295X2005X 2134 |

1295X2005X 2438 |

1000X1700X 1800 |

|

Body |

Fabricated with ISA 65x65x8 M.S , Plate 12 swg |

yes |

yes |

yes |

yes |

|

Outer shell of drum is of |

S.S 304, 16 Gauge, |

yes |

yes |

yes |

yes |

|

High Power Rare Earth Neodymium Magnet |

5000 Gauss. |

yes |

yes |

yes |

yes |

|

Toggle & Outer Body |

fabricated in M.S |

yes |

yes |

yes |

yes |

|

MOTORS |

Unbalanced motor KW; 960 RPM |

0.75 |

later |

later |

0.75 |

|

|

Geared Motor KW; RPM- 960 |

0.75 |

later |

later |

0.75 |

|

Weight |

Kg Approx. |

550 |

550 |

850 |

450 |

|

After-sale service |

Training, technical support, etc. |

yes |

yes |

yes |

yes |

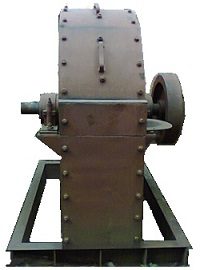

HAMMER MILL

|

DESIGN BASE |

2.5 Ton/hour |

5 Ton/hour |

10 Ton/hour |

|

|

General Information |

Model |

PEIE-2.5-X |

PEIE-5-X |

PEIE-20-X |

|

|

Max. Feeding Size (mm) |

<50 mm |

<50 mm |

<50 mm |

|

|

Output Size |

<10 mm |

<10 mm |

<10 mm |

|

|

Motor Power (KW X RPM) |

22 X 960 |

45X1440 |

75X1440 |

|

Overall Dimensions |

L X H X W (mm) |

later |

later |

later |

|

Body Chamber |

Fully fabricated M.S Plate IS-1062 |

Ø1000 mm |

Ø1370 mm |

Ø1000X1000 |

|

|

Shell thickness |

12 mm |

12 mm |

12 mm |

|

Liner |

Mn Steel IS: 276 Grade III Side |

20 mm |

25 mm |

25 mm |

|

|

Top Thickness |

30 mm |

50 mm |

50 mm |

|

Fly wheel |

heavy duty both sides, Matls.- C.I gr.-I |

450X80W |

Ø590X115W |

Ø700X150W |

|

Screen |

EN-9 square |

no |

yes |

yes |

|

Hammer |

Quantity |

8 |

8 |

|

|

|

Material |

C.S. Hard faced |

C.S. Hard faced |

C.S. Hard faced |

|

Inlet hopper size |

|

300X300mm |

450X450 mm |

500X500 |

|

Shaft |

material En-19 |

Ø104 |

Ø104 |

Chrome Nickel Axle Steel |

|

Weight |

Approx. |

1.8 Ton |

3 Tons |

4.8 |

|

After-sale service |

Training, technical support, etc. |

yes |

yes |

yes |

CONVEYOR BELTS Applications:

Applications:

Conveyors used here to convey in process material from one equipment bottom to next equipment top.

Belt Conveyors chosen here for granular bulk quantity, dust resistivity and low cost.

Belt Conveyors chosen here for granular bulk quantity, dust resistivity and low cost.

Features:

Light structure, stable performance, Convenient maintenance and economical running expense.

|

DESIGN BASE |

500 mm |

650 mm |

800 mm |

1000 mm |

|

|

General Information |

Model |

PEIE-500-X |

PEIE-650-X |

PEIE-800-X |

PEIE-1000-X |

|

|

Ton/hour |

< 150 |

< 200 |

< 400 |

< 630 |

|

|

Belt speed m/sec |

1.6-2.0 |

yes |

yes |

yes |

|

|

Conveying length |

>9 |

>9 |

>12 |

>12 |

|

|

Slope |

14±5 |

14±5 |

14±5 |

14±5 |

|

|

Motor power KW |

> 2.2 |

> 2.2 |

>3.7 |

>3.7 |

|

|

Drive pulley Dia |

350 |

350 |

450 |

450 |

|

|

Idler dia |

89 |

89 |

89 |

108 |

|

Gallery |

ISMC, ISA |

100 |

150 |

200 |

200 |

|

Weight |

Approx. Tons |

>1.2 |

>1.5 |

>2 |

>2.2 |

|

After-sale service |

Training, technical support, etc. |

yes |

yes |

yes |

yes |

|

B.W |

SYM |

Rº |

A |

B |

C |

ØD |

L min |

E |

F |

G |

H |

Slot |

Ød |

Brg. No. |

Base ISA |

Stiffeners |

Qty |

|

500 |

A3 |

30º |

|

|

225 |

114.3 |

30 |

|

4 |

9 |

14 |

14x32 |

20 |

420204 |

L65XX65X5/6 |

Flat 25x5 |

|

|

650 |

A4 |

30º |

940 |

250 |

225 |

114.3 |

30 |

50 |

4 |

9 |

14 |

14x32 |

20 |

420204 |

L65XX65X5/6 |

Flat 25x5 |

290 |

|

800 |

A3 |

30º |

1090 |

315 |

225 |

114.3 |

30 |

70 |

4 |

9 |

14 |

14x32 |

20 |

420204 |

L65XX65X5/6 |

Flat 25x5 |

469 |

|

1000 |

A3 |

30º |

|

|

225 |

114.3 |

30 |

|

4 |

9 |

14 |

14x32 |

20 |

420204 |

L65XX65X5/6 |

Flat 25x5 |

|

VIBRATING SCREEN

Application:

Application:

Vibrating screens are used here for oversize screening and dust separation.

Features:

Wear resistant side plates, Light structure, stable performance, Convenient maintenance and economical running expense.

|

MODEL |

POWER (KW) |

SIEVING DIAMETER (MM) |

DIMENSIONL X W X H (MM) |

LAYER |

|

PEIE-400-1S |

0.18 |

320 |

580X580X660 |

1 |

|

PEIE-600-1S |

0.55 |

550 |

800X800X780 |

1 |

|

PEIE-800-1S |

0.75 |

750 |

900X900X930 |

1 |

|

PEIE-1000-1S |

1.5 |

950 |

1160X1160X1030 |

1 |

|

PEIE-1200-1S |

1.75 |

1150 |

1360X1360X1160 |

1 |

|

PEIE-1500-1S |

2.2 |

1450 |

1850X1850X1330 |

1 |

|

PEIE-1800-1S |

2.2 |

1750 |

2200X2200X1460 |

1 |

|

Step |

HIGHLIGHTS |

THROUGH |

|

1 |

Direct Iron scrap collection |

Iron catcher magnet |

|

2 |

Lump size Lowering from ≤ 300 to 100 mm 3 |

Jaw crusher |

|

3 |

Lump size Lowering to 15 mm 3 |

Roller crusher |

|

4 |

Beneficiation accuracy improvement |

Size separation screen |

|

5 |

40% Iron recovery and dust removal |

Magnetic Separator |

|

6 |

Disintegration for 68% Iron recovery |

Hammer Mill |

|

|

|

|

|

7 |

Semi Automatic Plant |

Basic design |

|

8 |

Less Manpower require |

Semi automatic production and minimum maintenance |

|

9 |

Sellable Non Mag fines by-product can be used to manufacture brick |

|

Futures:

Futures: Application:

Application:

Application:

Application: